CASE STUDY | KRAUSS MAFFEI

Krauss Maffei Extrusion – Pioneer Process Control

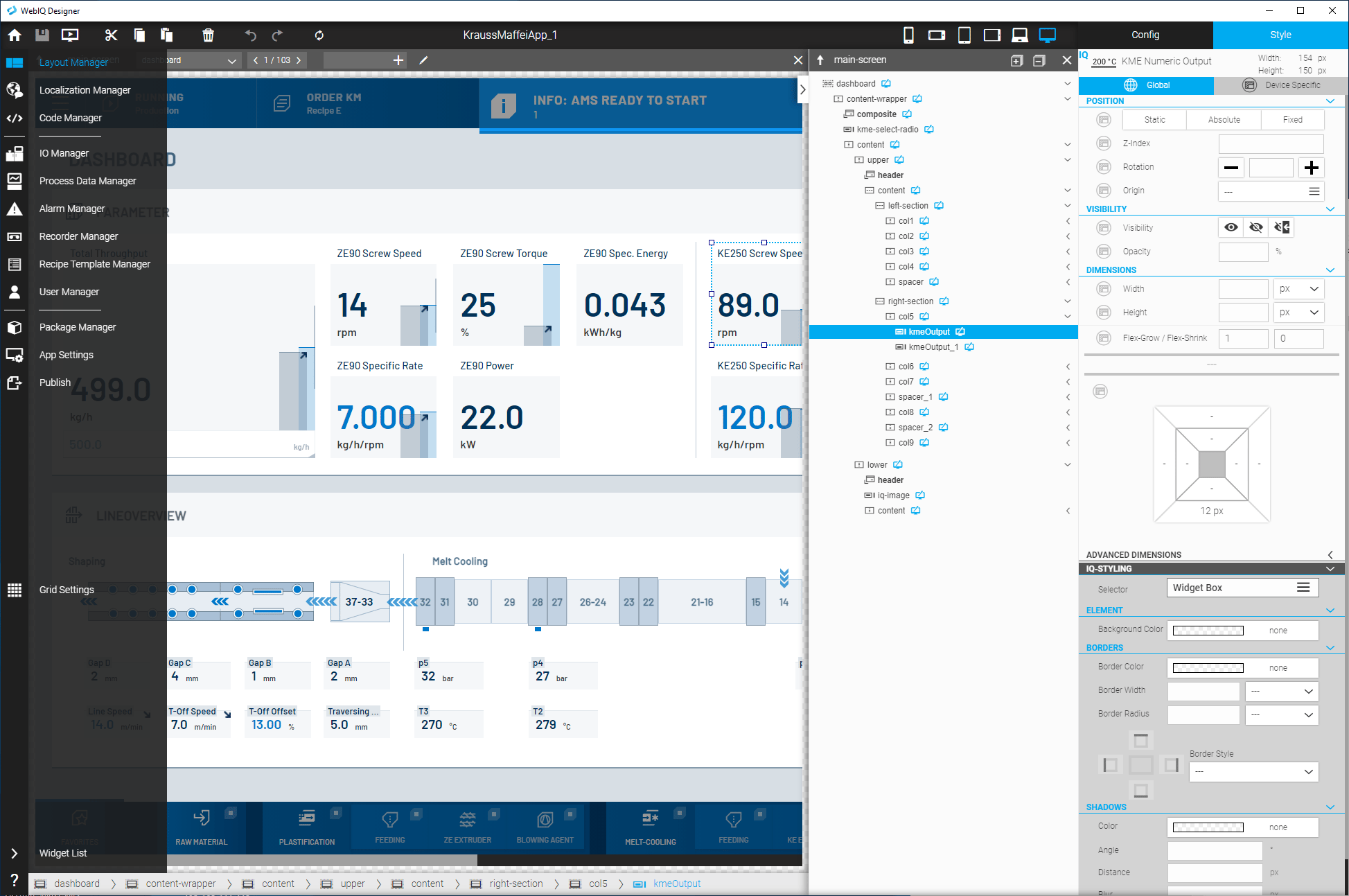

The solution was a web-based HMI with WebIQ

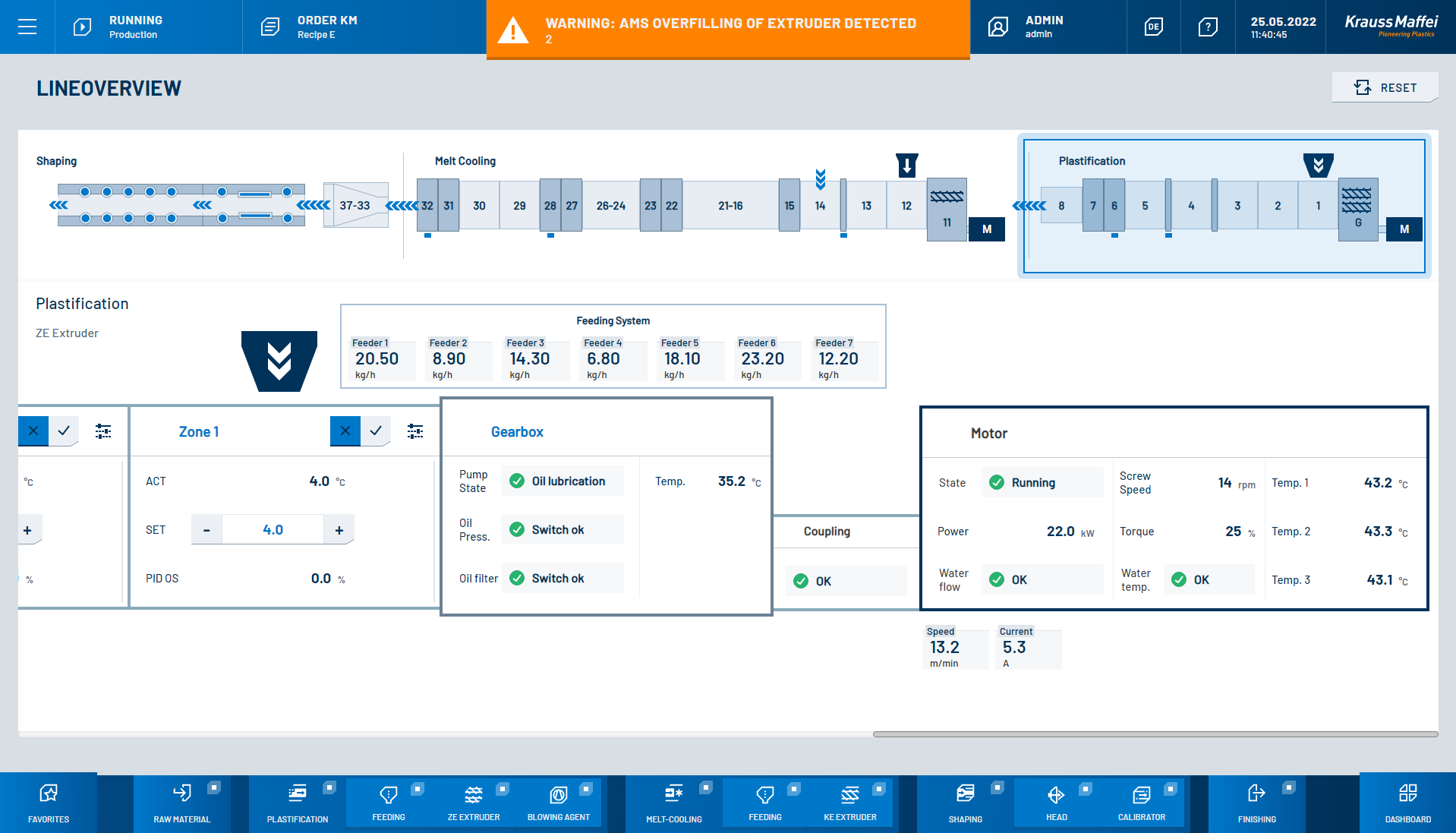

Krauss Maffei Extrusion provides high-performance machines and systems along the entire value chain for manufacturing nearly all extruded plastic and rubber products. With the goal of simplifying and harmonizing the complex and heterogeneous manifestations of the current user interface a flexible and modular system was developed, that can be transferred to other business segments in the future.

Design by HMI Project GmbH

Project Details

- Custom Widgets

- Development

- Empowerment

- HMI Creation

- Technical Support

- Workshops & Training

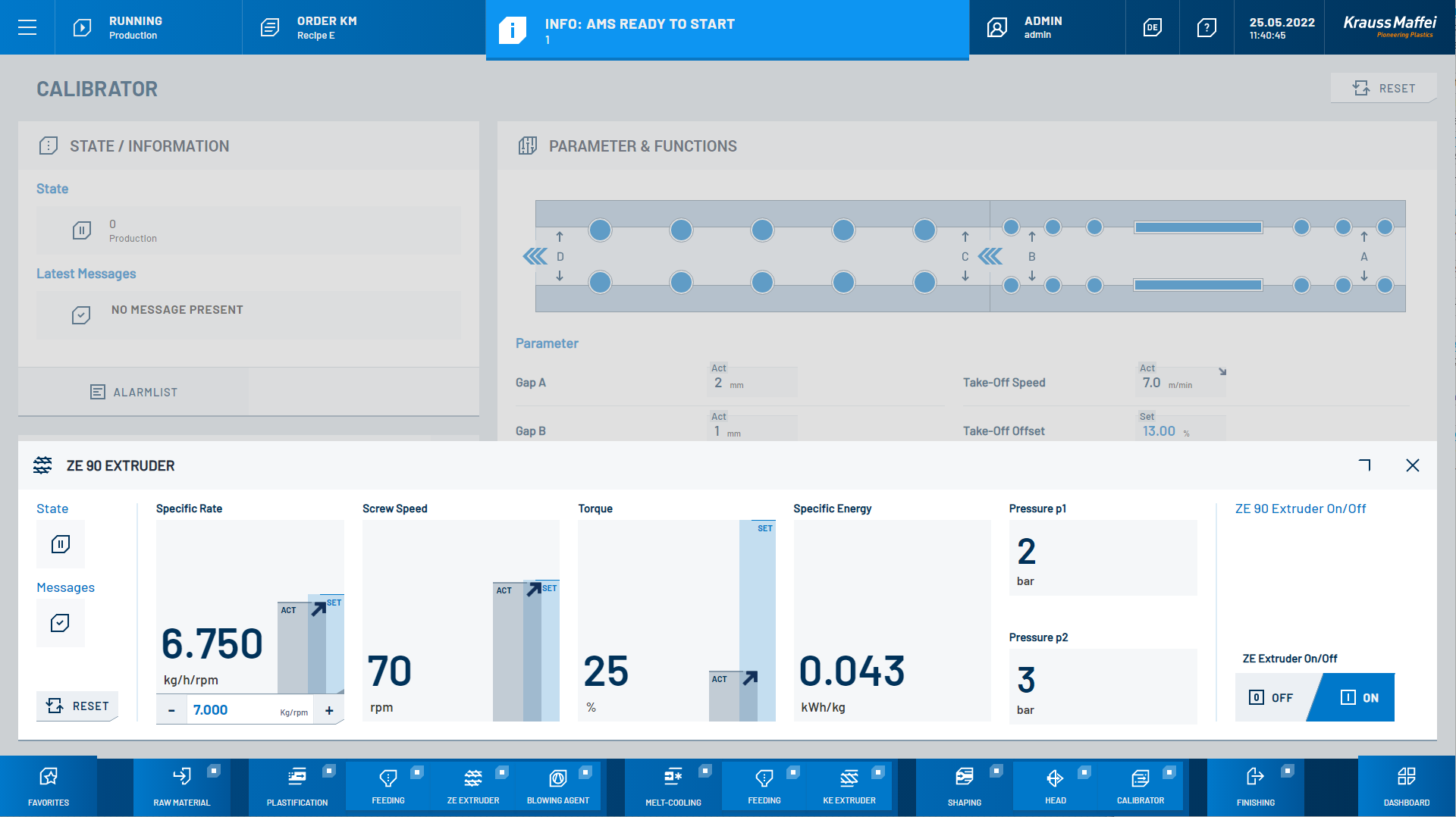

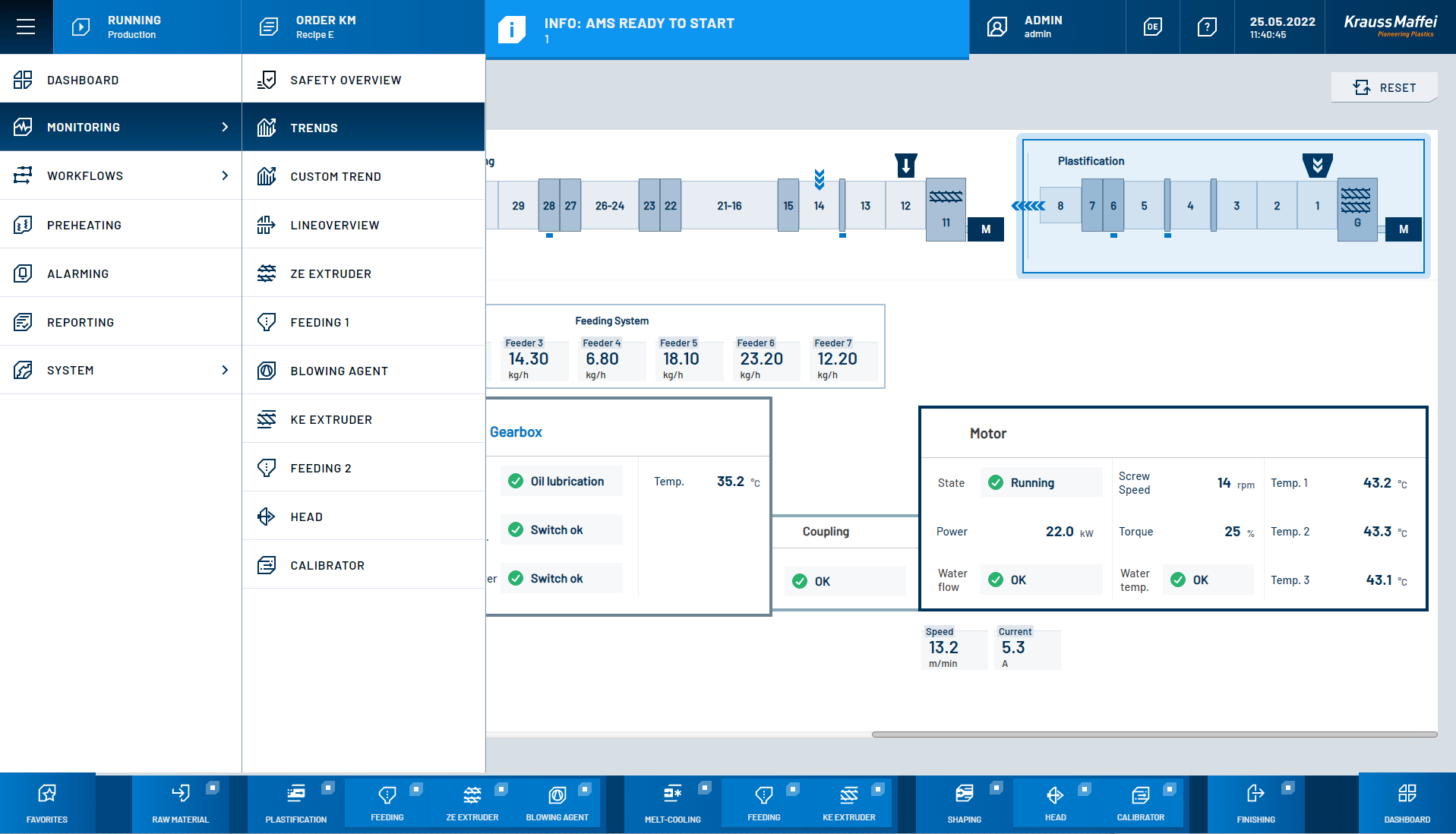

A great user experience was one of the main goals so a consistent and intuitive process-based navigation was created, that ensures clear overview, quick access and efficient operation.

With its extensive user, role and rights management, a clearly structured recipe management and reporting functions all realized in a responsive design the HMI adjusts perfectly to different screen sizes.

KraussMaffei chose WebIQ as the software platform for the web HMI – the unique style was achieved using custom styling with CSS and the creation of custom widgets allowing for the required unique functionality of the HMI.

Smart HMI created the main HMI according to the design and also took over the styling of widgets and custom widget creation in close and agile coordination with KraussMaffei. Continuous knowledge transfer happened already in the implementation phase allowing for KraussMaffei to take over the development of the HMI quickly and extending it regularly by having in-house users work on the HMI.

Sign up and experience WebIQ today!

Sign up now for free and download your copy of WebIQ – you'll also get access to all of our documentation and examples in our customer area.