CASE STUDY | FECKEN-KIRFEL

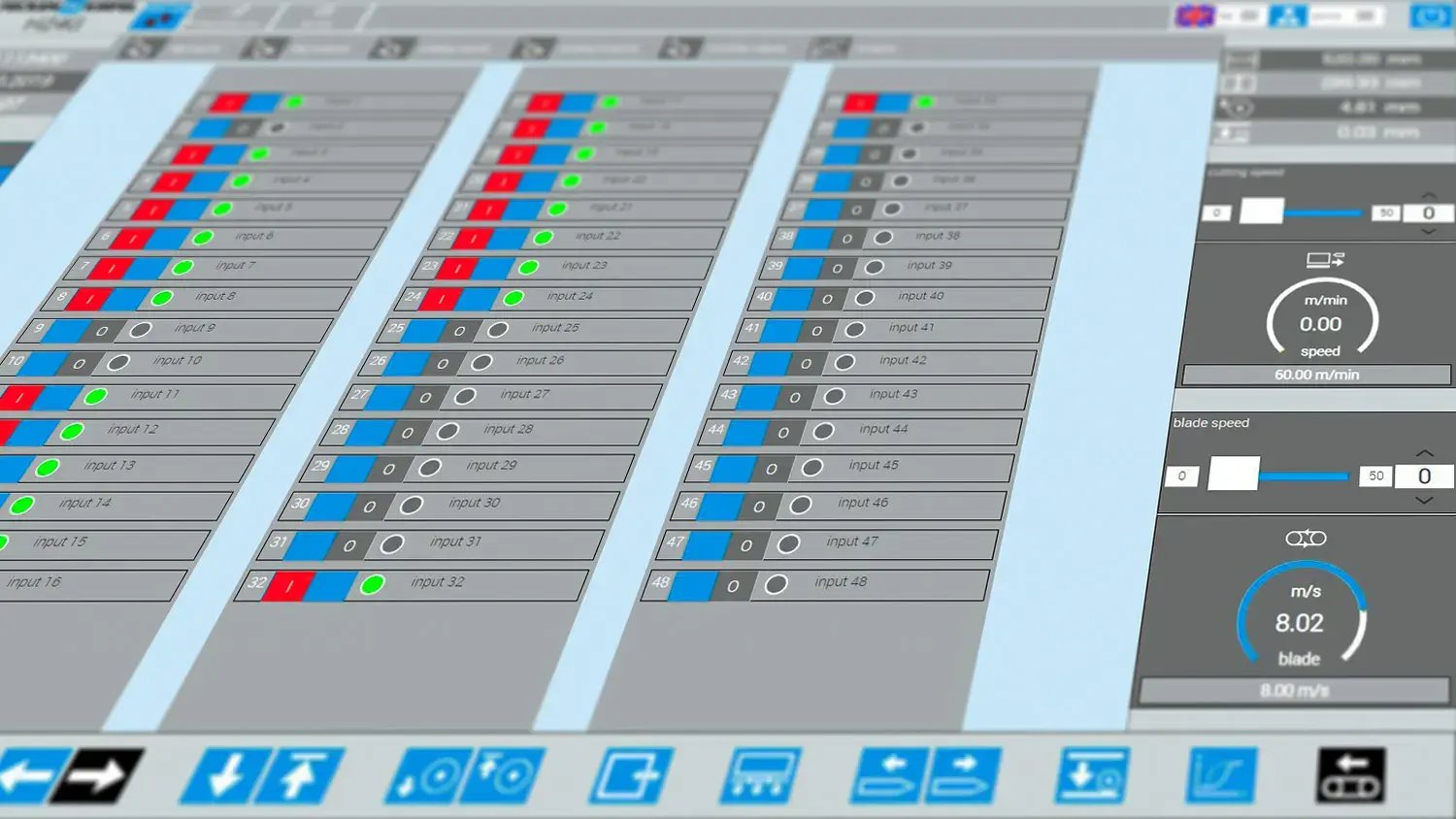

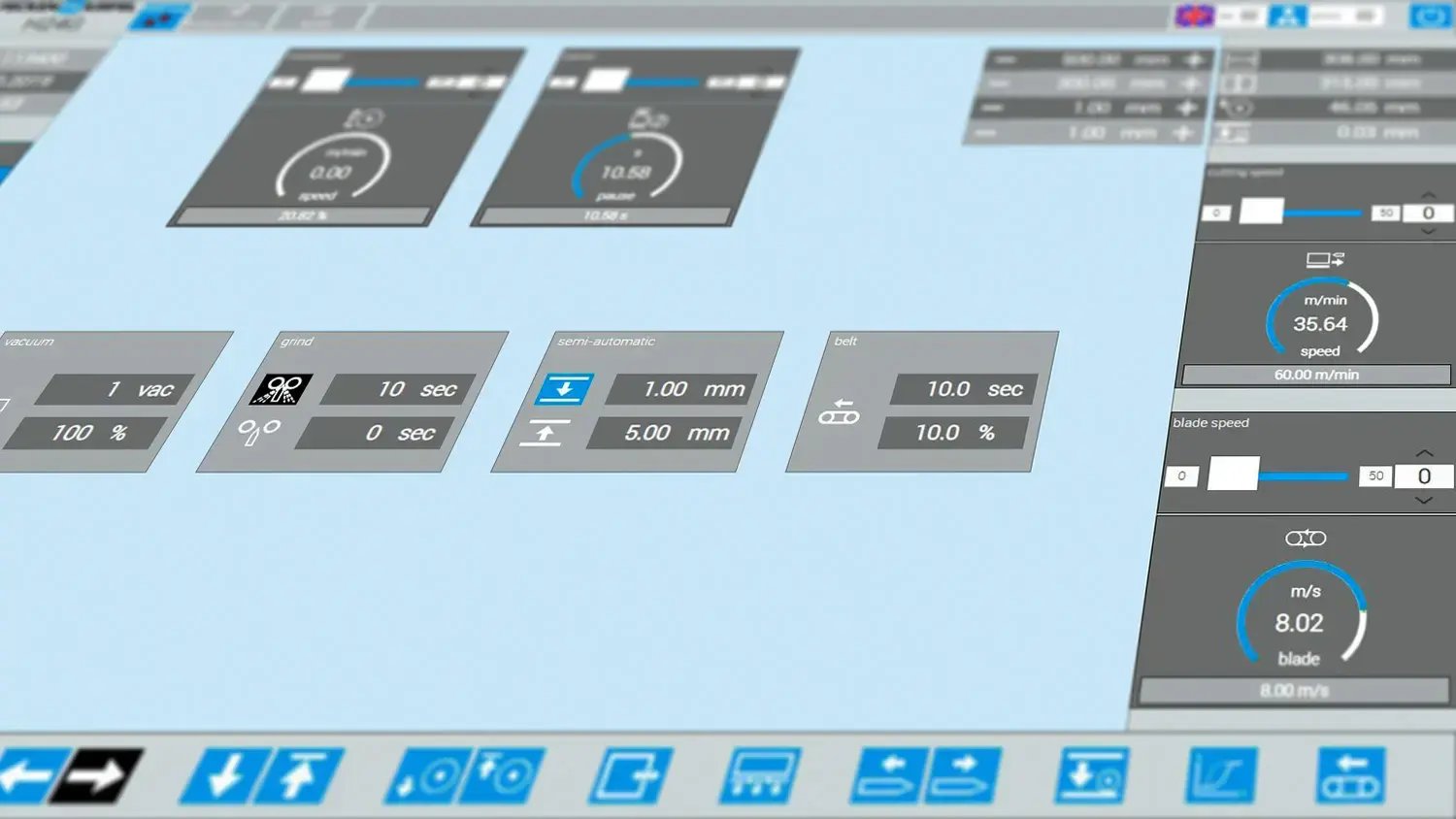

HMI Optimization With WebIQ

The solution was a web-based HMI with WebIQ

Fecken-Kirfel, the pioneers of cutting technology for flexible foam, compact plastics, hard foam and cork, have taken on a new challenge. The reliability and cost-effectiveness of the machines are undisputed, but the appearance and functionality of the HMIs used no longer fulfilled the company’s requirements. And so the HMI of the cutting machines came into focus.

What did we do

- WebIQ workshops and training on the job of Fecken-Kirfel employees

- Creation of an initial framework of the HMI as a basis for further development

- Custom widgets, such as the isometric machine view and tables for visualizing and editing process data

Fecken-Kirfel contracted Smart HMI – creators of WebIQ – for the development of a trend-setting, graphically high-quality web HMI. It was clear from the beginning: the development of the HMI had to stay at the company headquarters in Aachen! WebIQ met with enthusiasm and the will to implement the project mainly on their own. Smart HMI only provided selective support.

Although Fecken-Kirfel entered new territory when they started to implement the HMI with web technology, a very short time-to-market could be realized: only a few months passed from the project start up to the roll-out of the new HMI.

Although Fecken-Kirfel entered new territory when they started to implement the HMI with web technology, a very short time-to-market could be realized: only a few months passed from the project start up to the roll-out of the new HMI.

Sign up and experience WebIQ today!

Sign up now for free and download your copy of WebIQ – you'll also get access to all of our documentation and examples in our customer area.